Briquette Press

Biomass Briquette Press Biomass Briquette Plant Briquette Press Applications Support EquipmentBiomass Briquette Press

Briquetting is to compress incompact powder into a certain shape with high density and hardness. Biomass briquettes have high combustion rate. They are ideal substitute for coals in most usage scenario.

In general, there are 4 kinds of briquette presses:

- Screw Briquette Press is to process column briquette bars from sawdust, agro-waste etc.

- Roller Briquette Press is to process oval, pillow, square and other all kinds of shapes of briquettes from charcoal, coal and mine powder etc.

- Punching Briquette Press is to make coal ball, bricks and charcoal tablets etc. with all kinds of shape such as round, square, honeycomb and other patterns.

- Hydraulic briquette press is our newly developed products. It adopts hydraulic system and closed structure, which is able to process various materials. With Siemens intelligent PLC module inside, it achieves smart operation and high efficiency.

Biomass briquette plant

Briquette plant is a combination of a briquette press and a series of support equipments, used to turn agricultural and forestry waste into biomass briquettes. A biomass briquette plant contains wood chipper, wood crusher/hammer mill, dryer machine, briquette machine, pellet cooler, packager and conveyor. A carbonization furnace is necessary if you turn biomass briquettes into charcoal.

You can build you own biomass briquette plant with the equipments you need. We also provide customized products portfolio according to you situation, such as what raw materials you are going to process, and how much area you have. We can work out the most optimized solution to save your cost and enlarge your profit. But whatever portfolio you choose, the briquette press is indispensible. According to different briquette presses they adopts, our briquette plants can be categorized into screw briquette plant (200kg/h-1t/h) and punching briquette plant (500kg/h-5t/h).

Development of briquette press

Agriculture residues have long been the most important biomass fuel, for they widely exist in rural areas. However, bulky residues are difficult to burn, people are exploring various conversion techniques.

Biomass briquetting, also known as densification, has been practiced for many years. Nowadays, there are generally two types: screw briquette press and punching briquette press. The punching briquette machine adopt piston structure, and produce solid biomass briquettes, while crew briquette machine can produce briquettes with concentric holes, which present better combustion rate. Both hollow and solid briquettes are hard enough to avoid break.

Briquette press applications

The briquettes have many applications, such as brick used in building, coal or charcoal briquettes used for burning, shisha tablets used for smoking. The mine powder briquettes can be easily to transport and storage.

Coal briquette press

Coal powder briquette press: To make full use of the mine and coal wastes, we provide roller briquette press to compress powdery and granular products into compact biomass fuel. The briquettes can be produced with high or low pressure and can undergo mechanical or thermal treatment according to the characteristics of the materials, the binder used and the desired final product.

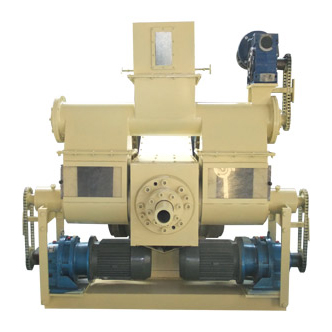

The roller briquette press has two larger roller mould in a fixed position in the frame, with the other two smaller rollers moveable to adjust the suitable pressure. Besides, there are another 2 rollers carrying out the second pressing, so the briquette is stronger and in higher density. The surface of briquettes will be smoother.

Coal Bar Briquette Press: The Coal Bar Briquetting Press is produced by screw type briquette press similar as biomass briquette press. The machine make the coal waste into bars for further burning, which is easy storage and usage.

Coal Ball Briquette Press: This series briquettes is used to make honeycomb coal balls. It adopts hydraulic briquette structure and can press coal and charcoal powder into various shapes of coal briquettes.

Raw material: coal briquette press can process coals, metallurgical slag powder, dry powder, metal magnesium powder etc. According to different materials, different compacting pressures are required. It has many applications in large industrial such as metallurgy field. The mine powder of color metal, black metal need to be compacted into ball for further smelt, such as dirt, oxidation skin, collected dust, metal fine powder, raw mine powder, manganese powder, silicon-manganese powder and other powder material.

Brick briquette press

With different briquetting molds, it can produce standard bricks, blocks, perforated bricks, paving bricks, etc. The machine achieves high working efficiency with automatic pallet conveyance, automatic leading-out and hydraulic molding. We are ready to supply a second raw material feeding system according to clients’ needs.

The series of brick and block making machine are solid and durable for its four guiding columns and patent lengthening sleeve guide. The forced mold synchronous structure gives the products perfect shape and high strength. And the stable demolding process ensures the output of more finished products.

What’s more, this series of brick briquette press achieves environmental protection with no polluted water, slag and waste steam discharge.

Shisha Charcoal Briquette Press

With the popularity of hookah smoking originated in Arabia, the demand for shisha charcoal is growing. Shisha charcoal briquette press is our self-developed products. The technology is mature and the production is high after several years’ experiments.

Shiasha charcoal briquette press is used to make charcoal dust and powder into small round tablets, which present high density, perfect shape, and good appearance. Meanwhile, it is easy for combustion, with long burning time and no smell. There are custom diameter of 22mm, 25mm, 33mm and 40mm tablets mould. The raw material feed to charcoal briquette press is powder from wood log or small sized biomass nuts such as coconut shell after carbonization.

With biomass briquetting plant, the waste charcoal chunk can be also well recycled to make into charcoal briquettes for barbecue or room heating etc. In this plant, binders are being used, and the yield will be 100% made of charcoal powder, chunks or waste pieces.

The charcoal briquette making of mixed charcoal powder, anthracite, binder etc after special technology compressed into barbeque charcoal briquette packed into bags. The product have no smoke, innocuity, no peculiar smell. The product have high heat value, can last barbecue time for 180 minutes. The binder can be chemical innocuity or natural biomass such as starch powder residue etc.