Flour Mill

Flour Mill Equipment Cleaning Equipments Roller Flour Mill Flour Mill Plant Flour Mills Plant ApplicationFlour Mill Equipment

We are experienced flour mill equipment manufacturer and supplier. Our product scope covers plansifter, purifier, flour mill, pneumatic flour mill, conveyor and all kinds of cleaning equipments.

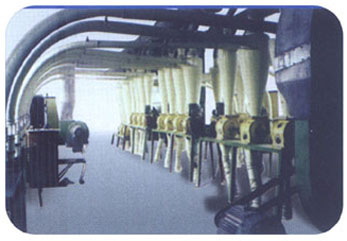

Flour Mill Plant

We are ready to offer turn-key solution of flour mill plant according to your needs. We absorb the international vadranced experience in flour milling field. The Grain Cleaning Equipments include three sifters, two scourers, two destoners, one separator, three magnetic selectors and two dampers. The Flour Milling equipments are plansifter, purifier, centrifugal impactor bran brush and other asstant equipment. We can install the divided flour and wheat systems with capacity to produce high precision gradational and special flour.

Roller Flour Mill

The 6FY, 6FS, 6FD series Flour Mills belong to small flour grinders. Because their grinding roller with diameter no more than 500mm. The capacity of the series flour mills are from 300kg per hour to 450kg per hour based on the feeding wheats. It can be well applied in many raw materials need to grind into powder, such as wheat, corn, pepper etc.

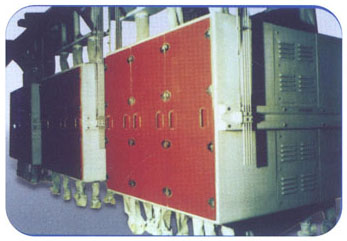

Pneumatic Flour Mill

The FMFQ series flour mills belong to big flour grinders. Their grinding roller press can be 600mm to 1500mm of diameter. They are well applied in large and middle flour milling plants. Their pneumatic transmission have much high efficiency which can control grinding process with better reasult.

Cleaning and Pretreatment Equipments

| 6CZD-45 Combined Cleaner | 6ZQS-36 Combined Cleaning Equipments | SDQ-25 Combined Cleaning Machine |

|

6XM-30/30A/40/50 Destoning, drying & Wheat Washing Machine |

TQLZ Series Vibrating Screen | FDMW Rotary Sieve |

| FDMW Series Wheat Scourer | TDTG Series Bucket Elevator | Screw Conveyer |

| FZSH Series Damper | TQSF Series Grading Destoner | TQZ Series Combined Cleaner |

| FDMW Series Wheat Scourer | TDTG Series Bucket Elevator | Screw Conveyer |

| FSF Series Double Storage Plasifter | SFZJ-43 Series Impact Detacher | Centrifugal Fan |

The Process of Wheat Flour Milling

Wheat Cleaning

After the wheat harvest, get off wheat granule by mechanical, and then bagging storaged into the plants. The wheat granule from anywhere are stored in granaries by elevators and mechanical conveying. The specialized persons select and classify wheat granule to remove impurities which will damage the flour milling machines and affect the quality of flour. The detailed process includes the following:

1. use wheat sieve to remove straw, broken husk, stone, hemp rope and other debris.2. use wheat selector to get rid of barley, oats, rye.

3. use air separator to remove dust, shell, bran and other light impurities according to different specific gravity.

4. use magnetic seperator to select the metal material out.

5. use washing machine to remove the sand and other non-magnetic impurities.

6. use dry type machine to remove the dust by friction.

7. use wheat washer to clean the tuft and the attached impurities, especially the material in the abdominal ditch of wheat granule. If there is smut in wheat, need add lime to clean the wheat grain.

Grain Conditioning

In order to make the followed flour milling work more smoothly and improve the extraction rate, we need water and suit temperature well for flour grinding according to different types of wheat grain. This process is known as conditioning. As to soak the purified wheat granule in water for 18 to 72 hours, the wheat grain will become flexile which bran and grain can be separated easily. Wheat granule are easy to be grinded. The malt become flat, screened out easily. The way to water is that spray out water at several times. For the same purpose, we need to condition the wheat grain into suitable temperature. First heated wheat grain to 42 ~ 45 ℃, and then cool them to the temperature same as room. At last, clean wheat grain, get granule separated from the husk and sent to milling.

Flour Grinding Operations

After fine pick, water and temperature condition, the wheat grain can be made bran, endosperm and malt separated to grinding operation. Becasue the endosperm and bran combined very close, the separation of them should be careful to scrape clean and minimize the damage in avoid of waste. The whole process is divided into coarse grinding, purification and reduction. Coarse grinding is by using two serrated steel roller shafts rotating running in opposite direction at different speeds, with upper roller faster than downside roller 2.5 times. Split the scarfskin of wheat gently and get out of coarse granule and bran in flat and big flaky shape. Through purification and keep the pure endosperm granule by fine separator accroding to different proportions. The light bran will float with injected wind power, the remaining heavier endosperm powder go to the reduction stage. After crush the endosperm by smooth roller flour mill, ground into powder. The crushed flat malt get out after germ separator (The process is what stone grinder can not work). Fine powder can be classified into different grade of flour by multi-storey rotary plansifter. The coarse granule sent to grind again (or use as bran). The fine particles can be cheap flour. The coarse debris sent to further processing to remove malt and fine debris, the fine debris can be fine ground into top quality flour.