Pellet Mill

Wood Pellet Mill Pellet Mill Applications Complete Pellet Plant Spare Parts Auxiliary EquipmentsWood Pellet Mill

As a widely used biomass machine, pellet mill can turn biomass materials like sawdust, rice husk, maize straw, branch and twigs into hard and smooth pellets. Wood pellets emerge as a substitute for fossil fuels, with the advantage of low cost, high heat value and low carbon emission. With the growing demand for biomass pellets, many users decide to have a pellet mill so as to make pellets by themselves.

We are a leading wood pellet mill manufacturer and supplier in China. With high efficiency administrative system approved by ISO9000, we can offer you best design and installation of wood pellet mills. Generally, there are flat die and ring die two types of pellet mills. Flat die pellet mill is suitable for home use and small-scale production, with low cost and energy consumption, while ring die pellet mill fits mid-scale and large-scale production, which features high production.

Pellet mill application

Pellet mills have both biomass fuel and animal feed two uses. So, they can be classified into feed pellet mill and biomass pellet mill two types. The raw materials for making feed pellets can be various fodders, such as grass, hay, rice husk and wheat bran. They have advantages over feed grass because they take up less place, with less dust content. What’s more, the pelletizing process promote the starch in feed to gelatinize and make it tastier and easier for animals to digest.

Biomass pellets serves as a new clean energy. With high combustion rate and low carbon emission, it gains popularity in house warming, cooking, industrial boiler and power generation. Biomass materials are easily available in the nature, like rice hull, bamboo, wood shaving, saw dust, waste paper and wood sticks. Besides, they are much cheaper than fossil fuels.

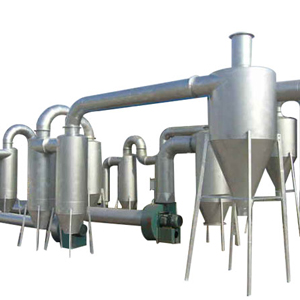

Complete pellet plant

A complete pellet plant is a combination of pellet mill and a series of support equipments, including pulverizing mill, dryer machine, pellet mill, cooling machine, sieving and bagging machines. Pellet plant is good at making biomass pellets for burning use. According to the pelletizing capacity and the pellet mill they adopt, there are small and large two sizes of pellet plant. What’s more, we’ve developed a mobile pellet plant which integrates all equipments for making pellets.

The flow chart of pellet plant is following

Raw Material - Pulverizing System - Dry System - Pelleting System - Cooling - Sieving - Bagging system

- Pulverizing System – hammer mill

- When the thickness of raw wood material is >10mm, and >50 * 50mm(L * W), we need use the Wood Chipper to chip them into small pieces, then crush the small pieces into wood powder with diameter less 3mm by Hammer Mill (wood crusher).

- Drying System

- The best moisture content to pelletizing is about 13-15%. Our Rotary Dryer is made up of Stove and Main Rotary Dryer, which can realize to reduce the moisture from 60% to 10%. Our stove is fueled by coal, which can save electricity consumption largely.

- Pelletizing System

- Driven with heavy- duty gearbox construction can produce continuously in most adverse condition. The imported key elements are of high performance with long life and low maintenance cost. The key parts are made of alloy steel to be very strong and malleable. Die is made of stainless steel. Pellet machine is widely used in the granulation of wood, straw, other biomass sources. capacity ranges from 200kgs to 3T per hour.

- Cooling /Sieving /Bagging system

- After the pelletizing process, the temperature of the wood pellet is about 60-80 degree, and the moisture content of the wood pellet is about 15%, so we need use Cooler to reduce about 3-4% moisture, such this the wood pellet is easy to store.

- After cooling, the wood pellet will not directly enter into the fuel process, avoiding the wood pellet affected with damp. The packing process is necessary. In this process, we assemble our domestic best Semi-Auto Packing Machine to you.

Auxiliary equipments

To meet different requirement for making pellets, we also supply all auxiliary equipment to match the pellet mill. These equipments are also necessary parts in pellet plant.

Among them, Hammer mill is the most frequently used one, because the raw materials must be pulverized into smaller sizes before fed into the pelletizing machine. we provide hammer mill of 2 sizes to meet different production capacity. The drive engine is also optional.

Dryer machine is a vital equipment before hammer mill and pellet machine. The moisture content of raw materials should be less than 18%, or it would influence the efficiency of making pellets and the quality of end products.

To feed raw materials into pellet mill, or transmit processed materials into the next procedure, we need conveyors to connect different equipments together. Our screw conveyor adopts portable design, and features high rotation speed, high loading capacity and stable performance.

Besides, we supply high-efficiency wood chipper, feed mixer, pellet cooler, packing machine and other support equipments for you to choose.

Technology Info on Pelletizing

The simply definition of pelletizing technology is to say the production process and methods in the producing of feed pellets,biomass pellets and wood pellets. The process of pelletizing can be divided into two classes: first crushed and then mix materials or first mix materials and then go to crushing process. The complete pellet mill for animal turn key plants and biomass wood pelletizing plants have their different design required by different features of raw material and final products.

The feed mill can be divided into several classes. For cattle, poultry etc, the feed pellet mill will be shorter in conditioner. For pig, pellet diameter usually be ø3.5-6.5mm. For cattle, the pellet diameter usually be ø4.5-8mm. For chicken, pellet diameter usually be ø3.2mm. Different structure of animal feed equipments have their special applicaiton in feed pellet mill.

At present, intensive management for feeding animal can save cost and realize maximum benebit. The feed pellet mills for animal turn key plants show its importance in the development of animal feeding. With the developing of intensive management of animal feeds, there is a big need of animal feed machinery in market.

Wood pellet mill and biomass pellet mill meet the new maket of biofuel. The agro-forestry waste are green enery for developing. They are clean and easy to storage. Wood pellets and biomass pellets are made from:

Groundnut-shell, Sugarcane Biogases, Caster Shells/Stalk, Sawdust, Coffee Husk, Paddy Straw, Sunflower Stalk, Cotton Stalks, Tobacco Waste, Mustard Stalk, Jute Waste, Bamboo Dust, Tea Waste, Wheat Straw, Palm Husk, Coir Pitch Barks/Straws, Rice Husks, Forestry Waste, Wood Chips and many other agro wastes.

The most suitable moisture of pellets material should be less than 12%, size is below 5*5 mm.

Introduction of PLC System

The Whole System adopt Siemens PLC controller, include motherboard, input & output module, software. MCC adopt Touch Panel, Simulation Control Screen or Computer Control Screen is optional.Automatic Moisture online testing, Automatic dosing, Automatic Lubricating, Automatic Steam supply, Lower Labor cost. 24 hours continuous working.

Raw Material for Biomass Pellets

Biomass pellets can be made of sawdust, cotton stalk, rice husk. All of these belong to biomass material. Beside them, any type of agro-forestry waste can be used, which becoming a new type of biofuel. Normally, the diameter of pellets are 6mm, 8mm and 10mm. They are compressed by both ring die pellet mill and flat die pellet mill. Flat die pellet mill is easy for family use or small workshop use. The pellets have slippery surface and hard core which won't be broken easily. They are clean renewable energy biofuel.

About Us

Specialized in the design, manufactuer and after-service of projects for feed pellet mills. We have special technical stuff in pursuit of developed technology of pelletizing, to design complete feed pelletizing plants at any capacity widely applied in feeding poultry, fish, cattle, pets, aquatic animals and other water livings.

With high efficiency administrative system approved by ISO9000, we can offer you best design and installation of wood pellet mills. After years' experience in wood pelletizing field, we have the advanced technolgoy of wood pelletizing. The raw material conditioning is very important for making wood pellets. Because wood waste are harder than feedstuff material which is not easy to compression. To adjust the material into suitable moisture and size can make good wood pellets.