Hammer Mill

What's the use of hammer mill?

We have to process raw materials into small size before feeding them into pellet mill or briquette machine. This is what hammer mill do for you. It is used to grind wood chips, wood shavings, small branches, straw, stalk, branches and other biomass wastes into 3-5 mm long. For most raw materials, they are not small enough to be fed into the pellet mill. A hammer mill is indispensible.

To match small and large pellet mill and pellet plant, there are two types of hammer mill for you to choose from. Small hammer mill is a basic part in small pellet mill plant, it can process corn straw, bean straw, peanut shell, corn and branches, etc, whose moisture content should be less than 14%. Clients usually buy hammer mills together with small pellet mill.

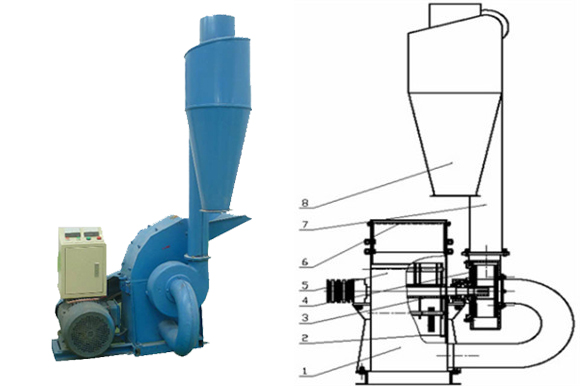

Small Hammer Mill

Small hammer mill is a basic part in small pellet mill plant, it can process corn straw, bean straw, peanut shell, corn and branches, etc, whose moisture content should be less than 14%. Clients usually buy hammer mills together with small pellet mill.

1. Lower body 2. Siever 3. Rotor 4. Air fan 5. Upper body 6. Feeding port 7. Discharging outlet 8. Cyclone

Small hammer mill parameters

Our hammer mill can be power by electric motor and diesel engine. The following are their parameters.

TFS500 hammer mill

| Model | Output Capacity (kg/h) | Power | Screen mesh (standard) | Hammer Quantity | Diamesion (mm) | Weight (kg) |

|---|---|---|---|---|---|---|

| FSP 158B | 100-200 | 2.2KW Single phase | 4 | 16 | 750*450*730 | 75/85 |

| FSP 198B | 240-400 | 3KW 3 phase | 4 | 16 | 1000*750*1120 | 120/135 |

| 4KW 3 phase | ||||||

| FSP 420B | 800-1000 | 7.5KW 3 phase | 5 | 16 | 1200*1000*1220 | 250/270 |

| 11KW 3 phase | 300/320 | |||||

| FSP500B -28 | 1000-1200 | 11KW 3 phase | 5 | 16 | 2200*1000*1020 | 470/500 |

| 15KW 3 phase | 500/530 | |||||

| FSP500B -40 | 1200-1700 | 22KW 3 phase | 5 | 24 | 2200*1050*1020 | 710/755 |

| 30KW 3 phase | 2200*1100*1270 | 800/835 | ||||

| FSP500B -60 | 1700-2100 | 37KW 3 phase | 5 | 36 | 2300*1150*1350 | 1150/1230 |

TFS420 hammer mill with diesel engine

| Model | Output Capacity (kg/h) | Power | Screen mesh (standard) | Hammer Quantity | Diamesion (mm) | Weight (kg) |

|---|---|---|---|---|---|---|

| FSP420A15 | 800-1000 | 15hp | 5 | 16 | 1650*800*1120 | 370/390 |

| FSP420A22 | 800-1000 | 22hp | 5 | 16 | 1650*800*1120 | 390/410 |

| FSP500A -28 | 1000-1200 | 22hp | 5 | 16 | 1650*800*1120 | 370/390 |

| FSP500A -40 | 1200-1700 | 55hp | 5 | 24 | 2250*1150*1270 | 995/1065 |

Large Hammer Mill

Large hammer mill is a basic equipment in large pellet plant. It can crush coarse fibers and large block materials like tree branches, bark, root , wood bricks, etc.

1. Feeding hoper 2. Iron remove 3. Outlet 4. Rotor 5. Air additional open

Performance features of large hammer mill

- The large hammer mill adopts welded-steel plate structure, with the electric motor and rotor installed on the same foundation.

- It’s convenient to match the conveyor system with large hammer mill because the feeding port is at the top of the hammer mill.

- By adopting belt transmission, it achieves high working efficiency. The rotor has passed dynamic balance check.

- The machine is easy to install and operate, with little vibration or noise.

Large Hammer Mill Parameters

| Model and specification | SFSPMX80×45 | SFSPMX80×60 | SFSPMX80×80 | SFSPMX80×100 |

|---|---|---|---|---|

| Production output (t/h) | 1.5~2 | 2~3 | 3~4 | 5~7 |

| Rotor diameter(mm) | 800 | 800 | 800 | 800 |

| Width of crushing chamber (mm) | 450 | 600 | 800 | 1000 |

| Main shaft speed (rpm) | 2400 | 2400 | 2400 | 2400 |

| Hammer quantity | 36 | 48 | 72 | 96 |

| Equipped power(kw) | 18.5/22 | 30/45 | 45/75 | 75/90/110 |

| Bearing model | NSK2216 | NSK 2216 | NSK 2317 | NSK 2317 |

| Belt model | C2692*5 | C2692*5 | C2692*5 | C2692*5 |

| Anti-vibration pad | 6 | 6 | 6 | 6 |

| Size of sieve mesh | 445*1250 | 595*1250 | 795*1250 | 995*1250 |

| Size (mm) | 2105*980*1600 | 2105*1172*1600 | 2105*1372*1600 | 2305*1520*1600 |