Pellet Mill : Conveyor

Conveying equipment play an important roles in transporting material from one mill to another, Some are designed to operate horizontally, some on a slope, others elevate the material vertically to a different level of the building. The requirement for elevators and conveyors will depend on how automated the mill is to be and how its plant is laid out.

The utmost use of such equipment is made in the modern pellet mill (often using pneumatic systems) to minimize labour needs and to maximise the use of land by building multi-storey, rather than horizontally arranged plants

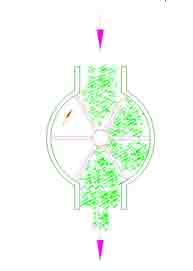

Airlocks: Lock the air, release the powder or granulated materials out.

Belt Conveyors: Belt Conveyor is used to transfer material or final product. It can be combined with other transfer equipments to build different transfer lines for mass production needs.

It is basically a conveyor consisting of two or more pulleys that have a continuous loop of material that rotates about them. Either one or both pulleys are powered and the belt moves along with the materials on the belt.

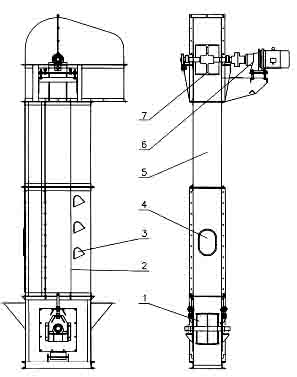

Bucket elevators: Bucket elevators are designed to gently transport a wide variety of products, both horizontally and vertically, transfer material to avoid damage. More used to lift the material to up level.

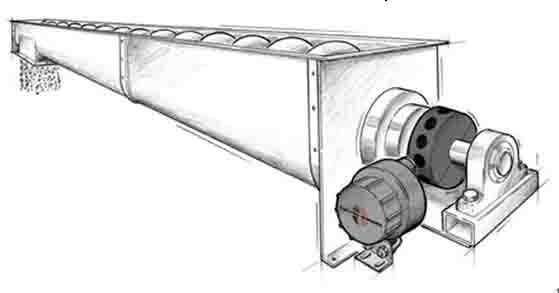

Screw Conveyors: Screw conveyors are used to convey materials such as bulk solids or sludge both on horizontal and high inclination, and are designed to provide an enclosed method of transferring materials from one point to another. It isconsisting of a screw inside a hollow pipe, contained within a tube and it is turned with the help of a motor in order to deliver material from one end of the conveyor to the other.