Railway Sleeper

Rail sleepers are also called rail ties. They are rectangular supports for rail tracks, placed perpendicular to the steel rails. They can transfer loads to the railroad bed, and keep the rail track in right place and correct gauge.

Traditionally, railway sleepers are made of wood, but in Europe and Asia today, prestressed concrete is widely used. Steel railway sleepers are widely used in UK for secondary lines, and plastic composite sleepers also plays a part. In general, the market share of wood railway sleeper is much more than that of concret, steel and plastic composite.

AGICO can supply you withUIC865 and BS-500 series steel rail sleepers. The following chart shows their specifications.

| UIC865 Series Steel Sleepers | |||

|---|---|---|---|

| SIZE | STANDARD | MATERIAL | LENGTH |

| UIC54 | UIC865 | According to customer's requirements | According to customer's requirements |

| UIC60 | |||

| BS-500 Series Steel Railway Sleepers | |||

|---|---|---|---|

| SIZE | STANDARD | MATERIAL | LENGTH |

| BS75A | BS 500-2000 |

SAE1522 ST52.3 20MnK SS490 Q255A |

1830mm 1900mm 2000mm |

| BS75R | |||

| BS80A | |||

| BS90A | |||

| BS100A | |||

| BS113A | |||

Different materials for rail sleepers

Wood railway sleeper

Wood rail sleepers has been used for centuries and still dominate the market. In US, the wooden sleepers take up 93% of the national railways. Wooden sleepers are usually made of hard wood like oak, while cheap wood like pines are used in light lines. Wooden rail sleepers is kind of resilient, with can reduce the load impact and diminish the noise and vibration.

Wood railway sleepers are light and cheap, easy to transport, install and maintain. It doesn’t requires complicate equipment or vehicles to maintain, so the cost-efficiency is high. The majority of wood railway sleepers are soaked in coal tar creosote improve their resistance to abrasion and insets.

Concrete sleeper

Concrete sleepers are made of cast concrete, with the interior reinforced by steel wire to improve the endurance for heavy load. The raw material, prestressed concrete can introduce the internal stress to the high-tensile steel wire skeleton. It has longer life-span than wood sleepers, and higher resistance to outward. Besides, it has less possibility to cause fire.

Concrete sleepers have dominate the railway in Australia. And the UK officials is replacing the wood railways sleepers gradually. Superior as concrete sleepers are, they have disadvantages of high transportation and installation cost.

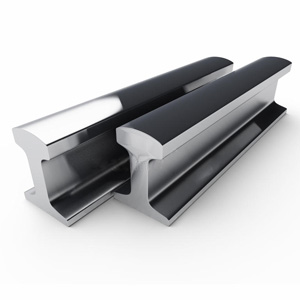

Steel Railway Sleepers

Steel rail sleepers are stronger than wood and cheaper than concrete, so they become the compromise between wood and concrete. Meanwhile, as it requires less ballast than concrete and wood, it is gets more popular, especially in place where wood is short.

However, steel railway sleepers are non-insulated. They need to be installed with neoprene composite insulators to protect the railway from electricity.

Plastic composite rail sleeper

Plastic composite rail sleepers are made of synthetic materials composed of plastic, rubber, waste fiberglass. It boasts the pliability of wood and the durability of concrete, which is a promising material. It can be sawed and processed like wood, and have similar life-span as concrete, without the heavy weight and complicated installation. Plastic composite rail sleeper can be installed piecemeal. As they are mostly made of recycled materials, they can be recycled to new sleepers.