Leaf Filter

The Leaf Filter has two type, vertical and horizontal. Vertical Leaf Filter have wide application. When big filtering area required, in order to discharge easily, horizontal leaf filter is used generally. Leaf filter was used in filtration of bleached oil and fat contented clay at early times. Recent years, after improvement of filter media and operation condition, the leaf filter is used into filtration of pressed crude oil to improve impurities which got perfect result.

The leaf filter have compact structure, which occupy small area. The filtration area of leaf filter is big and operation and maintenance is easy to master. If equipped with auto-control device, the leaf filter can realizes continuity, automation. As a result, the leaf filter have already been widely used in the separation of suspension material in crude oil.

Vertical Leaf Filter Oil Separator

The vertical leaf filter is mainly composed by tank, filtration leaf, support rod, oil collection pipe, residue discharge disc valve, vibrator, hydraulic jack and cover tight-lock device. The tank is a cylinder with disc cover and cone-shaped bottom. The filtration leaf is put between support rod and oil collection pipes. The oil output of every leaf is connected sealed with oil collection pipes through prejudicial press pole tightly pressed. The stainless steel filtration net put on the filtration leaf.

When working, the prepared oil for filtration is pressed into the tank by oil pump under certain pressure. The oil and fat pass through the filtration net of leaf into the clear oil channel of leaf. The clear oil is gathered into oil collection pipe to bring outside of machine. The suspension material is stopped at the surface of filtration net formed into filtration meal.

When the filtration meal reach certain thickness (limitation block volume is 1.0~1.2MPa), close the oil input valve and start compressing air. The oil and fat in the tank is transferred into another filter and pressed the left oil from residue and blow and clear the filtration meal by dry steam. After blow and clear away, decrease the pressure in tank and start the impulse vibrating device to make the filtration meal out of leaf, and open the bottom disk valve, discharge the filtration meal outside of tank by the left pressure inside. When residue discharge clearly, close disc valve and exchange related pipe valve, change into next filtration period. Making the two leaf filter parallel connection can realize the continuous filtration of crude oil.

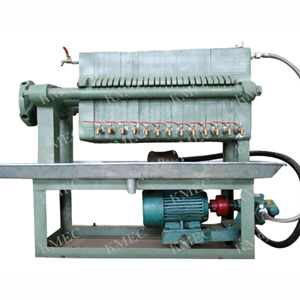

Horizontal Leaf Filter Oil Separator

The Leaf Filter has two type, vertical and horizontal. Vertical Leaf Filter have wide application. When big filtering area required, in order to discharge easily, horizontal leaf filter is used generally. Leaf filter was used in filtration of bleached oil and fat contented clay at early times. Recent years, after improvement of filter media and operation condition, the leaf filter is used into filtration of pressed crude oil to improve impurities which got perfect reasult.

Compared to vertical leaf filter, the horizontal leaf filter is much more easily to complete the work of discharge residue, which is processed by quick-open disc cover and push-pull device to pull leaf out of tank, so the cleaning of leaf will be more thorough.

The leaf filter have compact structure, which occupy small area. The filtration area of leaf filter is big and operation and maintainment is easy to master. If equipped with auto-control device, the leaf filter can realizes continuity, automatization. As a result, the leaf filter have already been widely used in the separation of suspension material in crude oil.