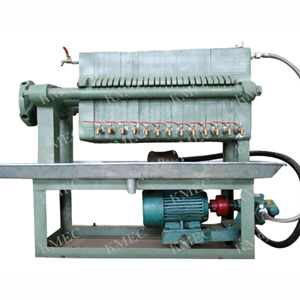

Oil Filter Press

The oil filter press/ plate filter press is used to separate the suspended solids in liquid, it can cooperate with oil press. This plate filter press is suitable for filter crude oil and refined oil, and it also applies to bleaching oil in the oil refining plants.

We’ve designed many kinds of filter press with different sizes and capacities to achieve the best filtration effect. Customized solution is also available to meet clients’ specific demands.

- The type of plate filter press are 200, 320, 450, 630, 800, 1000, 1250, 1500, Φ800 and Φ1000, and the filter area is from 0.5m2 to 500m2.

- They are made of cast iron, ductile iron, reinforced polypropylene, glass fiber polypropylene ( temperature 120℃) and stainless steel.

- The press principle are handle press, jack press, mechanical press, liquid press, automatic pressure and microcomputer control.

- The filter types are free flow, undercurrent flow, free flow wash out, undercurrent flow wash out, and two-way cross wash.

- The polypropylene is acid and alkali proof, non-toxic, non-smell, non-pollution, table and easy to handle.

- The whole series of filter press are in line with the national standard and passed the ISO9002 registration.

Working principle of Oil Filter press

The filter chamber is composed of filter boards and frames. As the suspension liquid is pumped into the filter room through the intermediaries such as filter cloth, filter paper and filter membrane, the solid particles and liquid are separated.

The filter board is also called diaphragm board, which is applied in wide range of industries, like petroleum, chemical industry, medicine, sugar, food, starch, dye, paint, metallurgy, coal washing, and sewage treatment.

Structure of Plate Filter Press

The filter press is mainly composed of mainframe, filtering parts, press and control. The filter part is constituted by several filter boards and frames which are ranked in the main beam in an order—the filter is between filter board and frame.

Mainframe

As the base of the machine, it play a role of linking the filter and other parts. It is made up of push plate, press board and frame and main beam. When the filter start working, the piston pole of the press frame push the press board so as to drive the filter board, filter frame and main beam to make sure the liquid in filter room continuously filter out.

Filter

The filter device is composed of several filter boards and frames connected with the main beam. The filter is between the filter board and frame. When raw materials are fed into the filter room by a push plate, the solid particles are trapped in the filter room while liquid flow out through the discharge hole under the propel of water flow, which is generated by the nozzle under each filter board.

Pressing device

The press part can be classified into handle/jack press, mechanical press, liquid press and automatic pressure press.

Handle/Jack Press: The handle press adopts the lever principle. As the small gear start rotate, it drive the large gear and press the clamping plate. It is easy to handle with one person.

Mechanical press: Under the action of motor and reducer, the large gear rotate and drive the clamping plate. You can switch the button to adjust the direction. This device is controlled by electric system. When the power reached the maximum, it can shut down automatically to protect the circuit.

Liquid press: When the crude oil is pumped into the oil cylinder through a control valve, the piston strain the press plate and form strong pressure to the oil.

Filtering Cloth

The plate filter press adopts a fine-mesh filtering cloth, which is particularly important for bio-diesel oil refinement. The filtrating cloth between the filter plates forms many rooms.

The oil is forced through the filtrating cloth and gets out from the faucet beneath the cloth.

Notes on Oil Filter Press Operation

- Tighten the pipe clips to prevent the oil leakage

- put the filtering cloth between the filter plate and tighten them with bolts.

- Generally, the oil will be expelled 2 or 3 minutes after the machine starts running. If no filtered oil comes out, please check the oil pipe for blockage.

- If the filtering cloth become torn or the oil looks dirty, you need to adjust the valve to maintain the machine.

Filter press operation

- Tighten the filtering plate.

- Open valve 4, and close valve 3.

- Start feeding pump 2 and let the crude oil go into the filter.

- Keep an eye on the pressure gage during processing. Adjust the filtering pressure to adapt to certain situation.

- Open the valve 3 and set the pressure bellow 0.6Mpa.

- Adjust the feeding pressure with valve 3.

- Close the feeding pump when the filtered oil become less.

- If you want to wash the plate, open the filtering plate and discharge filter cake. If the filter cake isn’t dry enough, it’s hard to open the plate. You have to close the filtering plate and go on the filtering process.

BAM Series Plate Filter Press

| Model | Filtering Area(㎡) |

Capacity of the filtering chamber(L) |

Overall dimension(mm) | Overall weight(mm) | Foundation dimension(mm) |

|---|---|---|---|---|---|

| BAMS1/320-30U | 1 | 15 | 1210*660*650 | 350 | 710*150*500 |

| BAMS2/320-30U | 2 | 31 | 1565*660*650 | 400 | 1020*150*500 |

| BAMS3/320-30U | 3 | 46 | 1875*660*650 | 455 | 1330*150*500 |

| BAMS4/450-30U | 4 | 61 | 1940*870*870 | 720 | 1160*180*600 |

| BAMS6/450-30U | 6 | 91 | 2250*870*870 | 800 | 1470*180*600 |

| BAMS8/450-30U | 8 | 122 | 2560*870*870 | 880 | 1780*180*600 |

| BAMS12/450-30U | 12 | 182 | 3160*870*870 | 1020 | 2380*180*600 |

| BAMS16/450-30U | 16 | 243 | 3770*870*870 | 1180 | 2990*180*600 |

| BAMJ20/630-30U | 20 | 298 | 3400*1150*1160 | 1980 | 2490*400*800 |

| BAMJ30/630-30U | 30 | 453 | 4220*1150*1160 | 2350 | 3310*400*800 |

| BAMJ40/630-30U | 40 | 595 | 4950*1150*1160 | 2680 | 4040*400*800 |

6LB Oil Filter Press

| Model | No.oil filter plates | Dimensions of filter plate | Working pressure | Productivity | Power | Dimension | Weight |

|---|---|---|---|---|---|---|---|

| 6LB-250 | 13pcs | 250*250mm | 0.3-0.4MPa | 100kg/h | 0.75Kw | 780*530*670mm | 155kg |

| 6LB-350 | 25pcs | 350*350mm | 0.3-0.4MPa | 200kg/h | 1.1Kw | 1300*750*700mm | 470kg |